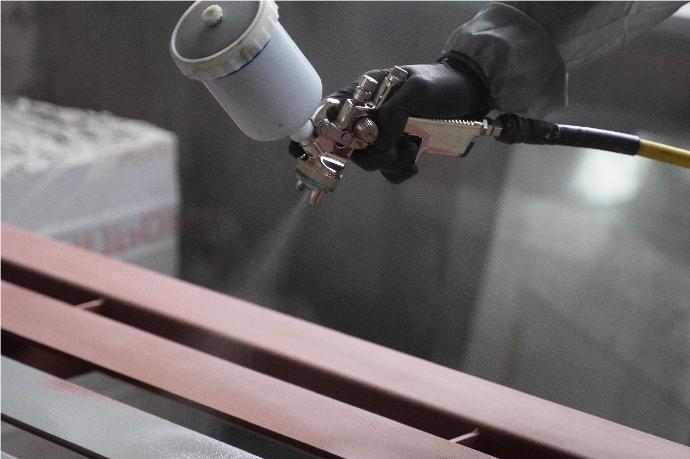

In sheet metal manufacturing, surface treatment technology not only enhances aesthetic appeal but also boosts corrosion and wear resistance, extending product life. Machan, with extensive experience and expertise, offers high-quality surface treatments, excelling in powder coating technology. By continuously innovating equipment and processes, Machan provides diverse coating options and customized services to meet varied customer needs. Their intelligent spraying systems and advanced surface pretreatment ensure superior product quality, positioning Machan as a reliable partner for all project requirements.

Common Surface Treatment Methods:

Electroplating

Principle:

Deposits a metal coating on the surface through electrochemical reactions to achieve corrosion resistance, increased hardness, and enhanced appearance.

Application:

Suitable for automotive parts, electronic products, and household appliances.

Machan Advantages:

● High-quality coating: Uses advanced technology to ensure uniform coatings with excellent corrosion resistance.

● Eco-friendly process: Employs non-toxic, environmentally friendly electroplating processes to reduce environmental impact.

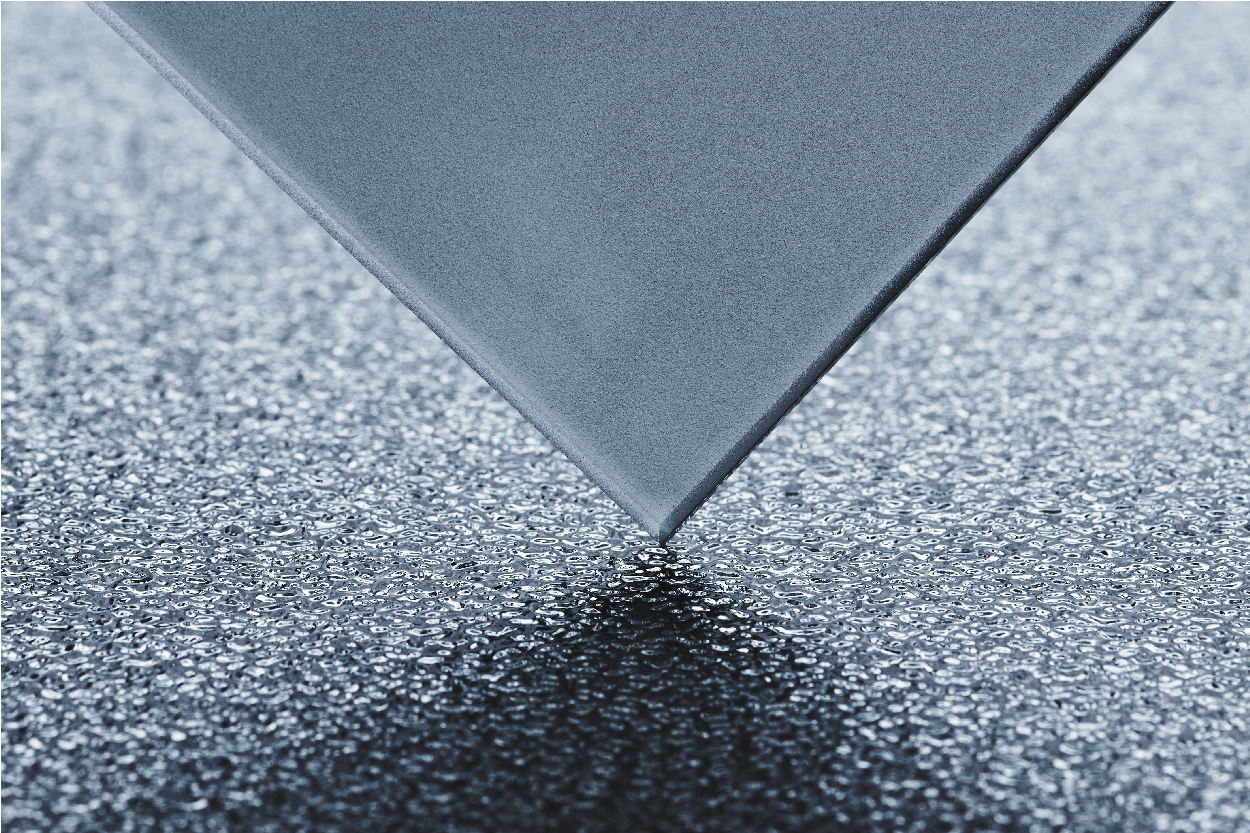

Powder Coating

Principle:

Uses electrostatic action to adsorb powder coatings onto metal surfaces, forming a dense film after high-temperature baking.

Application:

Suitable for outdoor furniture, machinery, and building materials.

Machan Advantages:

● Diverse color options: Provides a rich selection of colors to meet customer personalization needs.

● High wear resistance: Enhances product wear and impact resistance.

Anodizing

Principle:

Generates an oxide film on aluminum surfaces through electrolytic reactions, offering good corrosion resistance and decorative effects.

Application:

Used in aerospace, electronic product housings, and architectural decoration.

Machan Advantages:

● High-quality oxide layer: Forms a uniform and dense oxide film, enhancing corrosion resistance.

● High wear resistance: Accurately controls oxide layer thickness to meet various application needs.

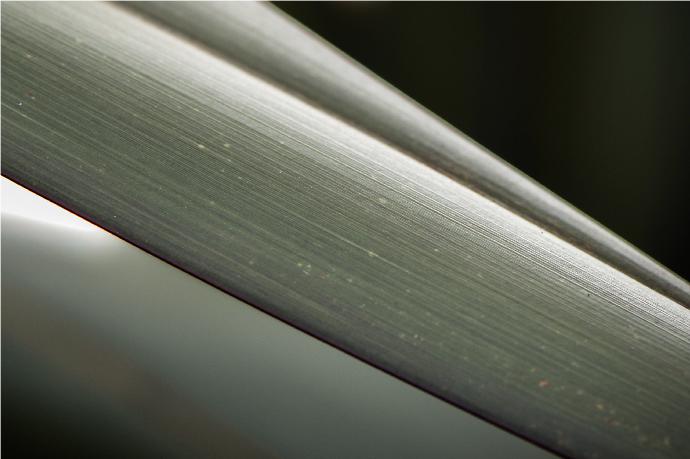

Sandblasting

Principle:

Uses high-speed sand flow to clean and roughen metal surfaces, improving surface quality and adhesion.

Application:

Suitable for subsequent painting or electroplating workpieces, and cleaning surface oxide layers and dirt.

Machan Advantages:

● Efficient cleaning: Effectively removes surface dirt and oxide layers.

● Uniform surface roughening: Enhances coating adhesion and durability.